Manufacturer And Supplier

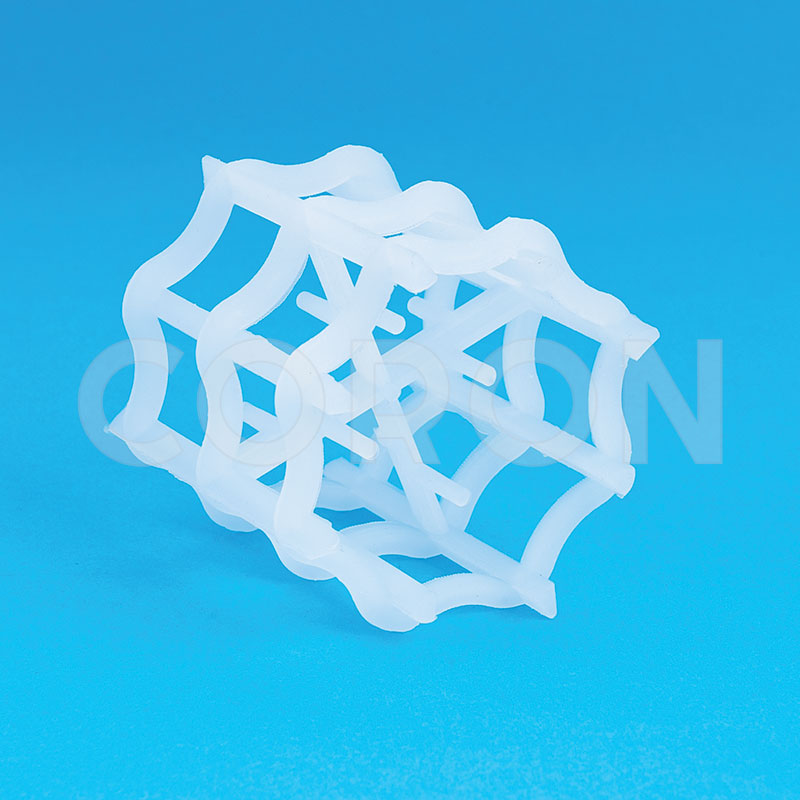

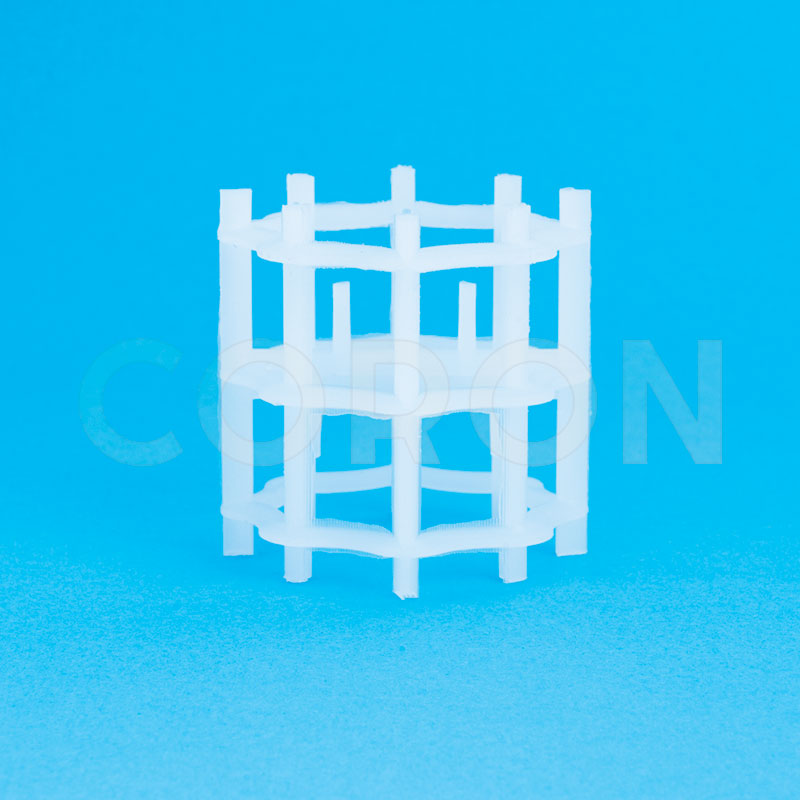

VSP Tower Packing

VSP Tower Packing has very high void ratio, low pressure drop, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, small specific gravity, high efficiency of mass transfer.

VSP is designed in a way that is proportional and symmetrical in all dimensions, allowing for accurate scale-up without the risk of nesting.

They have heavy ribs for added strength, making them suitable for use in high bed heights.

Specifications

| Size | Surface Area m2/m3 |

Pcs. Per m3 |

Voidage % |

|---|---|---|---|

| 25 mm | 185 | 48,000 | 93 |

| 50 mm | 100 | 6,500 | 95 |

| 90 mm | 78 | 1,150 | 97 |

VSP Tower Packing

Application And Benifits

- VSP is widely used in petroleum and chemical, alkali chloride, gas and environmental protection industries.

- Their special structure makes it a big flux, low pressure drop, good anti-impaction capability.

- They also have large void space, energy saving, low operation cost and east to load and unload.

Material Of Construction

- PP : Polypropylene

- PP-LTHA : Polypropylene - Long Term Heat Aging

- GFPP : Glass Reinforced Polypropylene

- PVDF : Polyvinylidene Fluoride

- PVC : Polyvinyl Chloride

- HDPE : High Density Poly Ethylene

- CPVC : Chlorinated Polyvinyl Chloride

- PFA : Perfluoroalkoxy

- FEP : Fluorinated Ethylene Propylene

- ETFE : Ethylene Tetrafluoroethylene

- ECTFE : Ethylene Chlorotrifluoroethylele

- PPS : Polyphenylene Sulfide

Note: Other Materials are available on request.