Manufacturer And Supplier

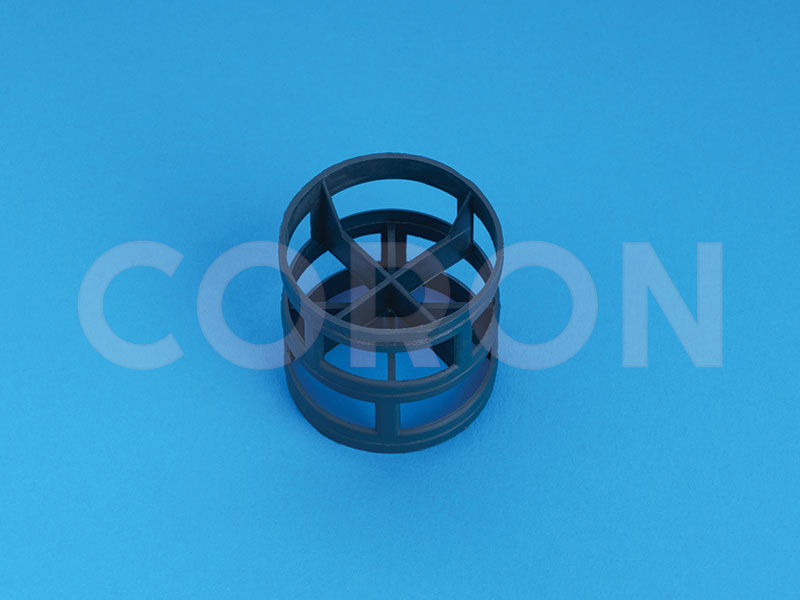

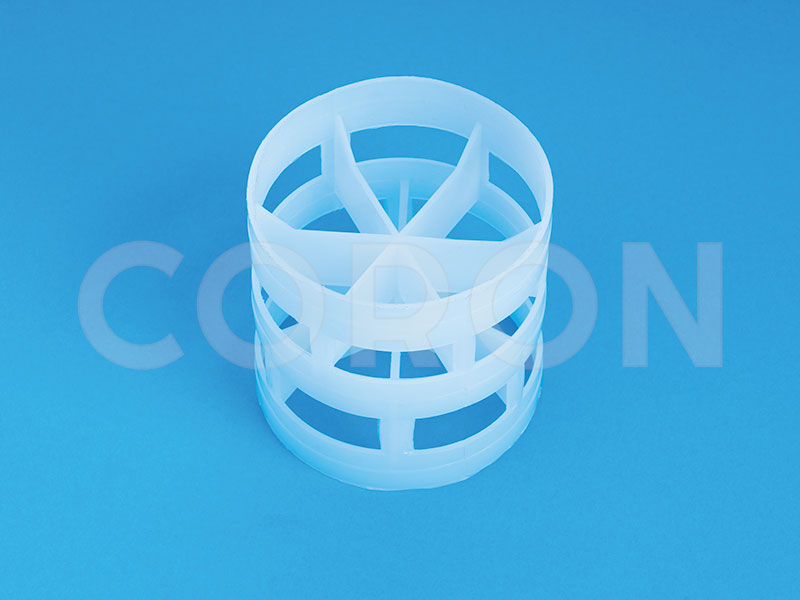

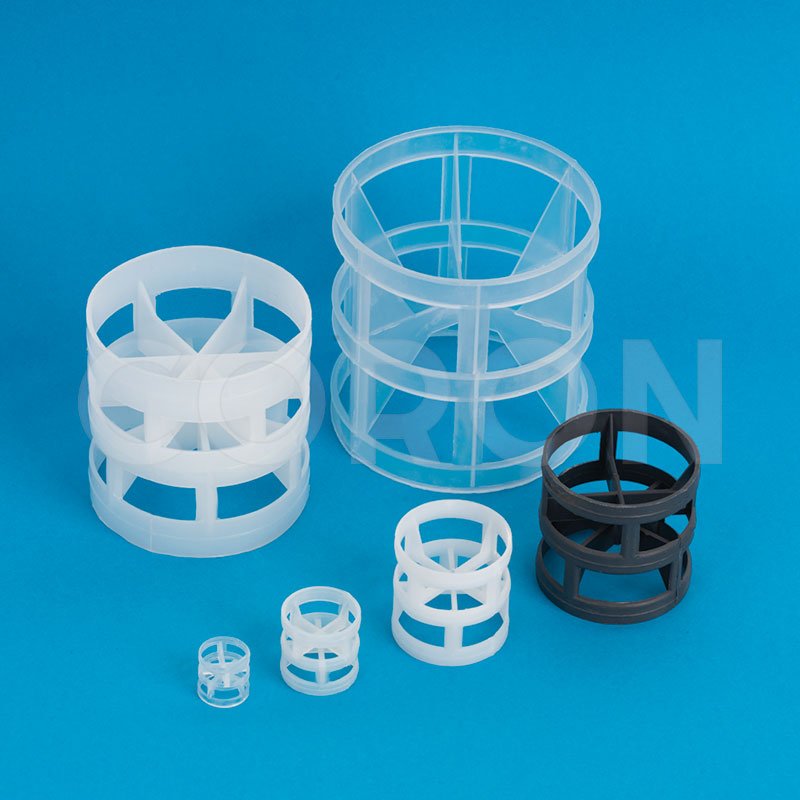

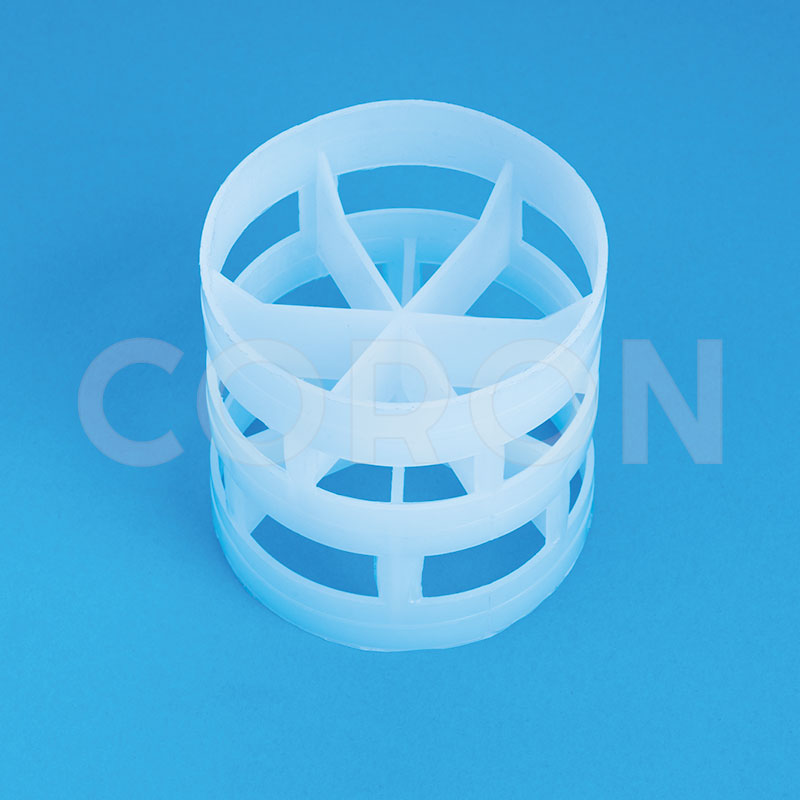

Plastic Pall Ring Tower Packing

The innovative design of our plastic pall ring tower packing significantly increases its performance in terms of efficiency, pressure drop & throughput.

Pall rings have internal support structures & external surfacing.

The texture within the rings allows for points of internal dripping that significantly increases the capacity & the efficiency of the packing.

Specifications

| Size | Surface Area m2/m3 |

Voidage % |

Pcs. Per m3 |

Packing Factor F |

|---|---|---|---|---|

| 16 mm | 340 | 80 | 2,10,000 | 95 |

| 25 mm | 210 | 90 | 51,000 | 52 |

| 38 mm | 130 | 92 | 15,000 | 32 |

| 50 mm | 100 | 93 | 6,500 | 25 |

| 75 mm | 92 | 95 | 2,100 | 20 |

| 90 mm | 85 | 96 | 1,200 | 16 |

Plastic Pall Ring Tower Packing

Application And Benifits

- Plastic pall rings are among the most commonly used tower packing materials for applications involving gas and liquid separation.

- Their ability to withstand corrosive environments, they are mainly used in chemical process towers.

- Few other applications include CO2 absorption, SO2, HCl and HF absorption or stripping, and chlorine and chlorine dioxide absorption in water or caustics.

- Find more creative ideas for your projects

Material Of Construction

- PP : Polypropylene

- PP-LTHA : Polypropylene - Long Term Heat Aging

- GFPP : Glass Reinforced Polypropylene

- PVDF : Polyvinylidene Fluoride

- PVC : Polyvinyl Chloride

- HDPE : High Density Poly Ethylene

- CPVC : Chlorinated Polyvinyl Chloride

- PFA : Perfluoroalkoxy

- FEP : Fluorinated Ethylene Propylene

- ETFE : Ethylene Tetrafluoroethylene

- ECTFE : Ethylene Chlorotrifluoroethylele

- PPS : Polyphenylene Sulfide

Note: Other Materials are available on request.