Manufacturer And Supplier

Carbon Raschig Rings

Carbon Raschig Rings are made from high-purity carbon, Electric furnaces fire at very high temperatures, therefore it is an entirely carbonizing process.

Specifications

| Size mm |

Surface Area m2/m3 |

Pcs. per m3 |

Voidage % |

Bulk Weight Kg/m3 |

|---|---|---|---|---|

| 13 x 10 x 13 | 393 | 3,76,000 | 67 | 400 |

| 19 x 12 x 19 | 256 | 1,25,000 | 58 | 595 |

| 25 x 16 x 25 | 190 | 48,200 | 60 | 590 |

| 32 x 22 x 32 | 124 | 19,450 | 67 | 525 |

| 38 x 24 x 38 | 119 | 13,200 | 60 | 570 |

| 38 x 30 x 38 | 128 | 14,200 | 76 | 390 |

| 40 x 28 x 40 | 118 | 11,900 | 68 | 485 |

| 50 x 38 x 50 | 93 | 5,950 | 68 | 415 |

| 75 x 49 x 75 | 62 | 1,800 | 64 | 518 |

| 76 x 59 x 76 | 60 | 1,850 | 76 | 350 |

Carbon Raschig Rings

Application And Benifits

- Our Carbon Raschig Rings are having 99% Carbon and very low content of Ash which therefore makes these rings strongly resistant towards all Acids, Alkalis, Solvents, Mixtures and many more chemicals.

- This is useful in petrochemical projects as they have very long life, high efficiency for corrosive and temperature separations as well as shock resistance and high temperature stability.

- Carbon Raschig rings are used in Halogen Acid processing, Hydrofluoric Acid manufacturing, Sodium/Potassium Hydroxide Scrubbers & Chlorine Hydrochloric mixturesment.

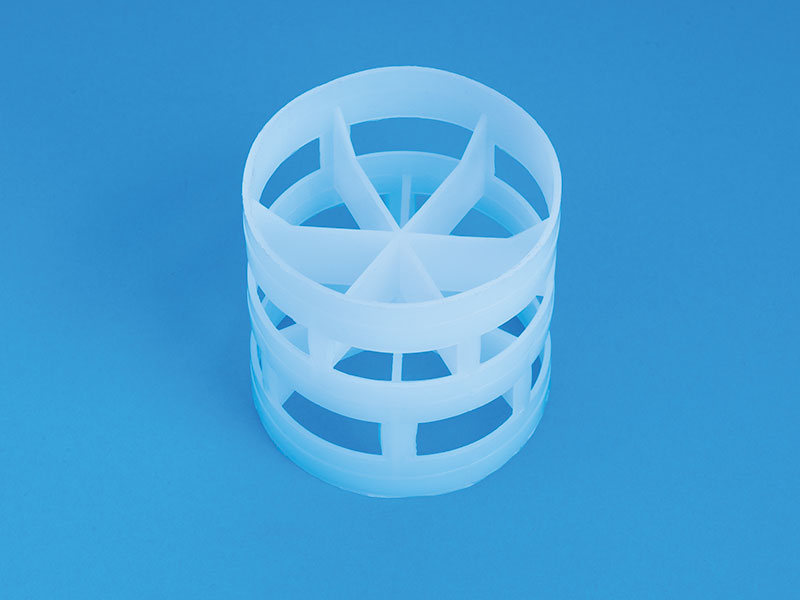

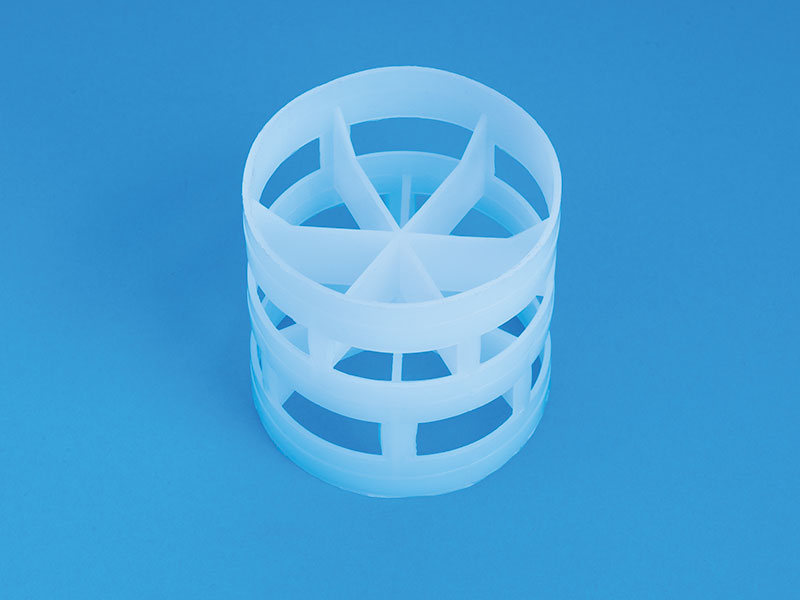

Material Of Construction

- PP : Polypropylene

- PP-LTHA : Polypropylene - Long Term Heat Aging

- GFPP : Glass Reinforced Polypropylene

- PVDF : Polyvinylidene Fluoride

- PVC : Polyvinyl Chloride

- HDPE : High Density Poly Ethylene

- CPVC : Chlorinated Polyvinyl Chloride

- PFA : Perfluoroalkoxy

- FEP : Fluorinated Ethylene Propylene

- ETFE : Ethylene Tetrafluoroethylene

- ECTFE : Ethylene Chlorotrifluoroethylele

- PPS : Polyphenylene Sulfide

Note: Other Materials are available on request.