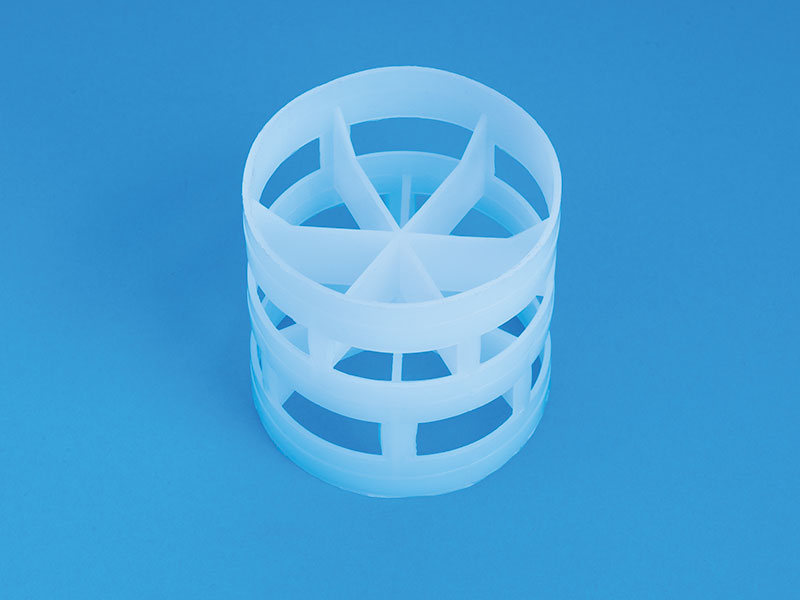

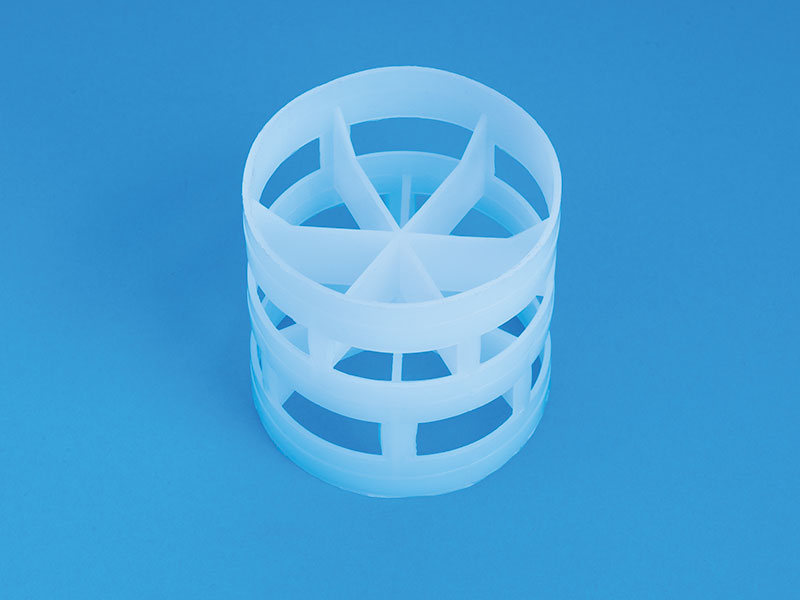

Random Tower Packing

- Random tower packing simply pours the filtration media into the tower.

- The uneven distribution and orientation of the parts increase the surface area and enhance the transfer of mass between two fluids.

- The benefits of random packing media comes from narrow tower without ready access.

- In some instances, random packing material may augment existing material to increase a tower’s capacity.

Plastic packings are used in corrosive applications with low to moderate operating temperatures and can offer an economic advantage over metal materials. Where temperature permits, plastic tower packings are better than ceramic packings. Plastic packings are mainly used in the absorption, scrubbing, stripping, and heat transfer services.

- CO2 Absorption

- SO2, HCl & HF Absorption Or Stripping

- Chlorine Absorption In Water Or Caustic

- Chlorine Dioxide Absorption

- Hydrogen Sulphide & Mercaptan Removal

- Air Pollution Control Scrubbers

- VOC Removal

- Decarbonation

- Deaeration

- Wastewater Treatment

- Drinking Water Preparation

- Fish Farming

- Humidification

- Dehumidification

- Direct contact cooler

- Water Chiller

Advantages

- Relatively InexpensiveCompared to structured packing, random packings provide a more cost-effective method of filling a tower. The design, material and amount you choose will ultimately determine the final cost.

- High strength-to-weight ratioThe individual pieces, especially those made from more durable materials, have a high ratio of strength-to-weight. Overall, the random packing media can physically endure mechanical stress well, especially in relation to their lightweight construction.

- Ease of use in difficult-to-access sitesRandom packing materials have an easy to install method that does not require frequent servicing as trays do. For narrow towers with hard-to-reach openings, using random packing material will provide a better option.

When choosing random packing materials, several factors will narrow down the options available for your application. Ask yourself the following questions:

- Is the material a direct replacement of the existing packing you use?

- Do you know the type of packing and performance you require?

- Does the media work with your process?

To help you decide if a media works with your process, consider its surface area, wetting area, friction, and other performance factors to find the ideal option to use in your tower.

- Surface Area

Increase efficiency by choosing random packings with a greater surface area. The more surface area per volume of the packing, the higher the vapor-liquid contact. The surface area you get from your media depends on multiple other factors, including the size and shape of the pieces.

- Wetting Rate

Each material has an inherent wetting rate. If the liquid load drops below the wetting rate, the surfaces of the packings will dry out. The effects of liquids dropping below the wetting rate for the given material include decreased efficiency.

- Uniformity of Distribution

The benefit of random packing is the lack of structure the material creates. When pieces interlock, they can create paths for fluid flow. When fluids have the chance to move along channels, the system loses efficiency.

- Uniform Spreading Surface

How the surfaces of the media spread fluids determines their efficiency. While surface area plays an important part in how efficiently the system operates, when pieces have a uniform spreading surface to allow more vapor-liquid contact, the packing works better.

- Package Voidage

Increasing the amount of void space as much as possible reduces the chances the media will slow down the upward movement of vapor through the system. Due to more void space inside the parts, the capacity of a tower will rise when using larger random packing pieces.

- Friction

Lower friction for packing media opens spaces between the pieces and inside them. With more space, the tower has a greater capacity and operates more efficiently.

- Packing Strength

The mechanical strength of the material should withstand compression and other damage from typical use in a tower. Resisting corrosion and thermal damage also contributes to the overall strength of a packing medium.

- Packing Material

The materials available include plastics, ceramics, carbon, glass, and PTFE.