Manufacturer And Supplier

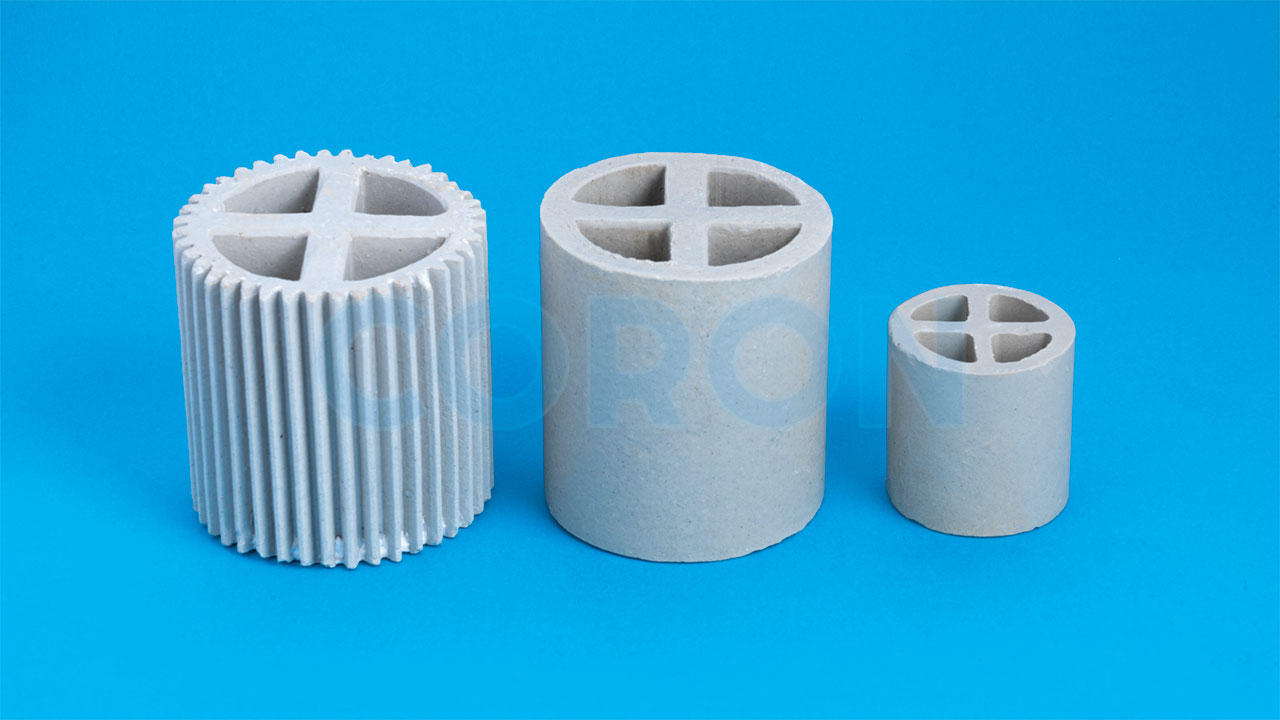

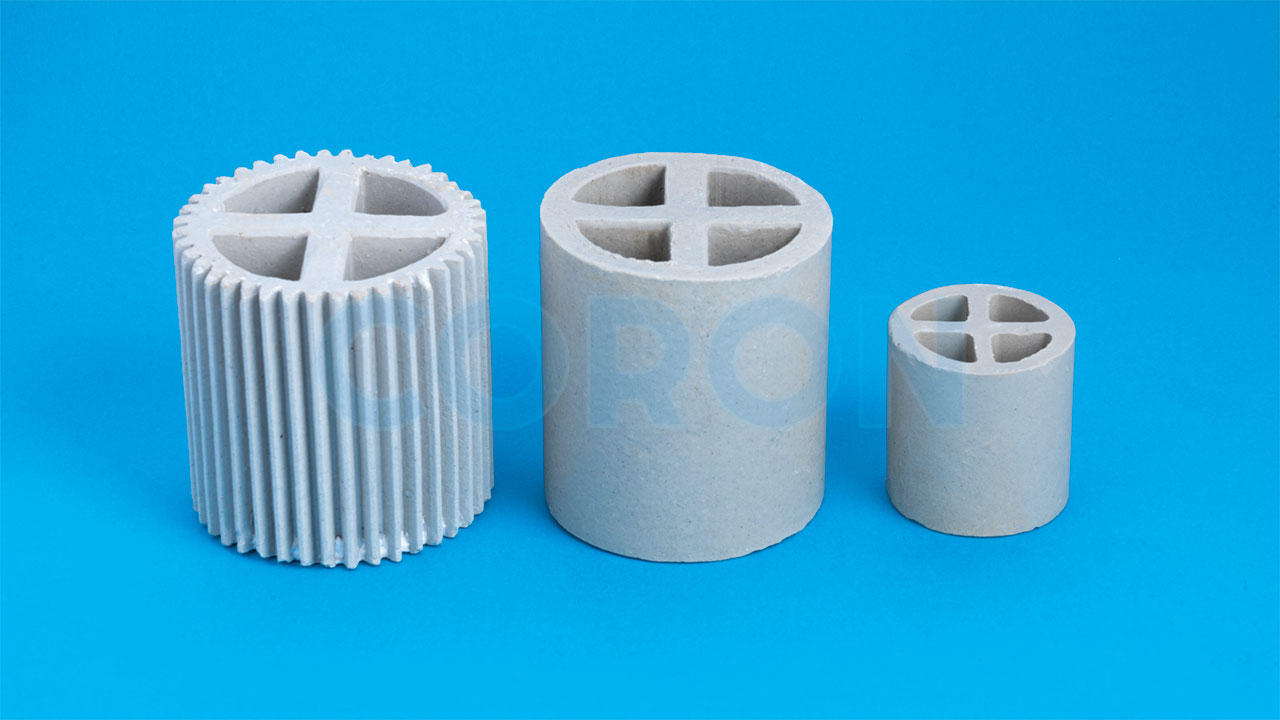

Ceramic Rachig Ring 4 Partition

Ceramic Rachig Ring 4 Partition has a better surface area and compressive strength.

Ceramic Rachig Ring 4 Partition has excellent acid resistance and heat resistance performance.

It can withstand various inorganic acids and organic solvents except for hydrofluoric acid and can be used in high or low-temperature conditions.

Specifications

| Size |

|---|

| 75 mm |

| 100 mm |

| 120 mm |

| 150 mm |

| 200 x 150 (mm ht) |

Chemical Properties Of Ceramic

| Sio2 + Al2o3 | >92% | CaO | <1.0% |

| Si02 | >76% | MgO | <0.5% |

| Al2O3 | >17% | K20 + Na2O | <3.5% |

| Fe2o3 | <1.0% | Other | <1% |

Physical Properties Of Ceramic

| Water Absorption | <0.5% | Moh’s Hardness | >6.5 scale |

| Porosity | <1.0% | Acid Resistance | >85% |

| Maximum Operating Temperature | 1200°C | ||

Ceramic Rachig Ring 4 Partition

Application And Benifits

- It is widely used in high or low temperature conditions.

- Ceramic Raschig rings are widely used in the drying tower, absorption tower, cooling tower and washing tower in chemical, metallurgy, coal gas and industrial oxygen production industries.

- It is acid and alkali resistant.

- It has low pressure drop and high mass transfer efficiency.

- It has high compressive strength. It has better surface area.