Manufacturer And Supplier

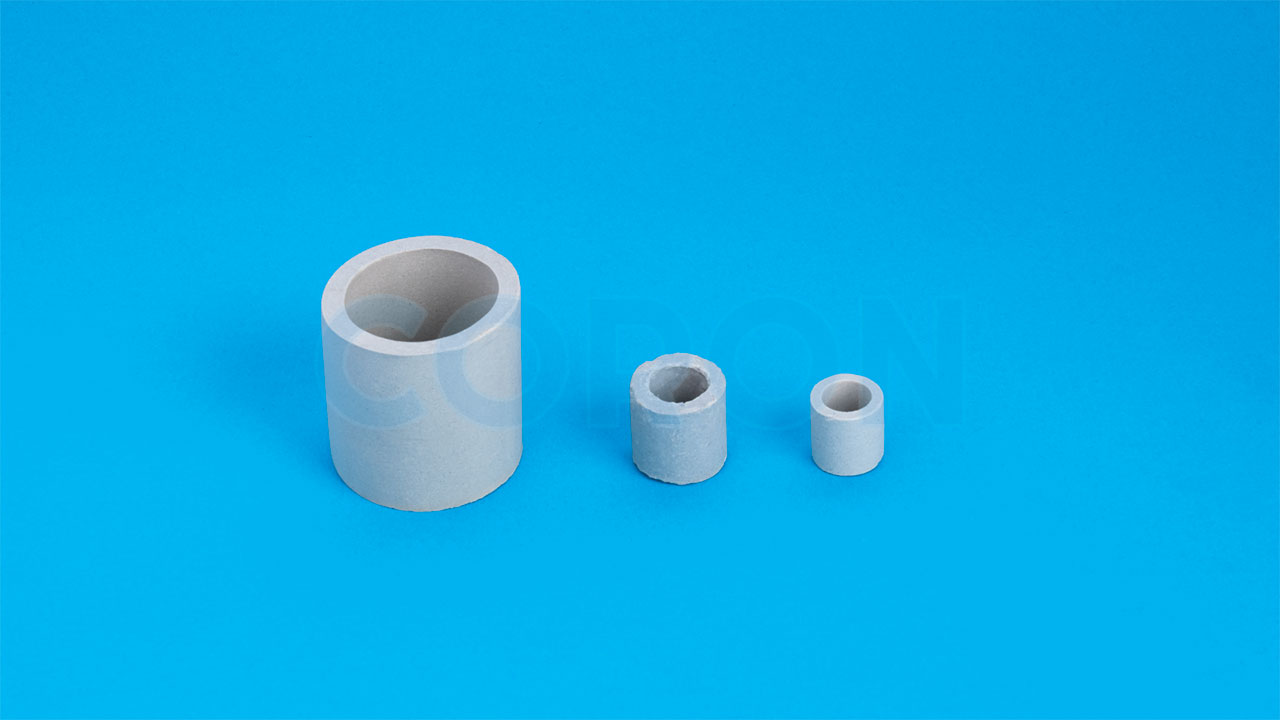

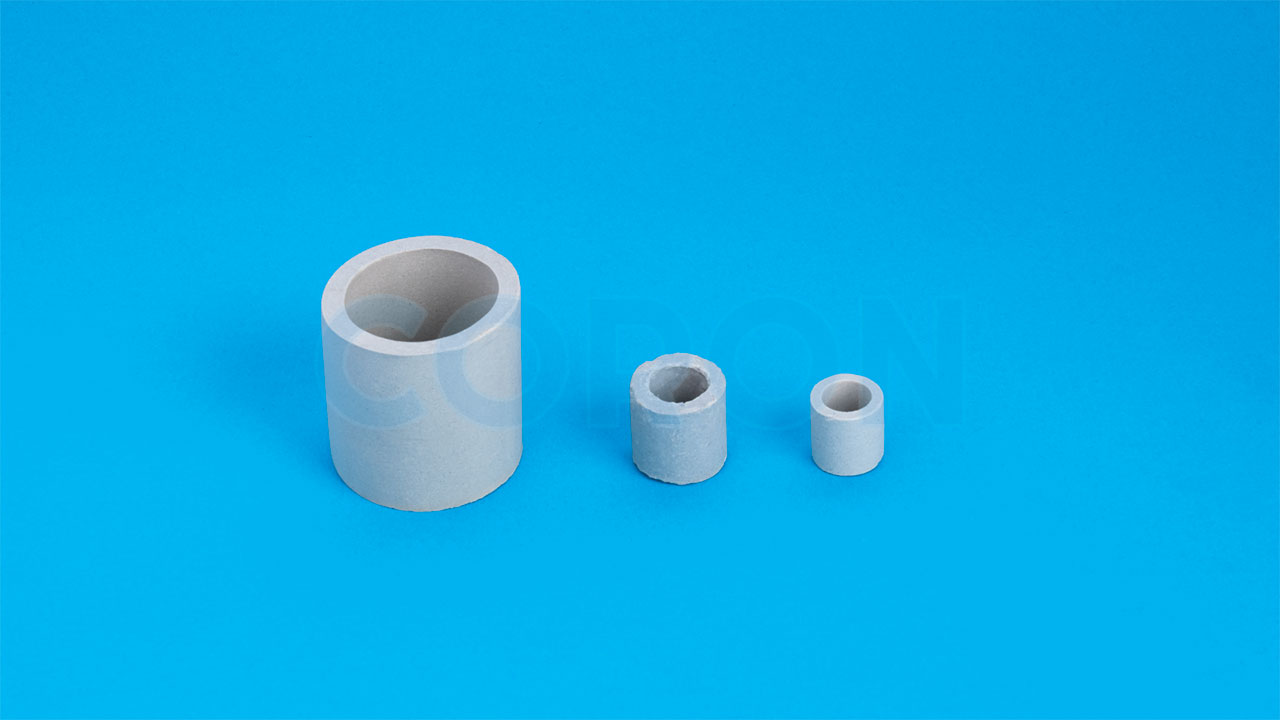

Ceramic Raschig Ring

Ceramic Raschig Ring has excellent acid resistance and heat resistance performance.

It can resist any inorganic acids and organic solvents except for hydrofluoric acid.

Specifications

| Size | Surface Area m2/m3 |

Voidage % |

Bulk Density Kg/m3 |

Bulk Quantity Pcs./m3 |

|---|---|---|---|---|

| 15 mm | 330 | 70 | 650 | 560 |

| 20 mm | 240 | 73 | 640 | 255 |

| 25 mm | 195 | 73 | 625 | 155 |

| 38 mm | 140 | 76 | 560 | 95 |

| 50 mm | 98 | 77 | 540 | 65 |

| 80 mm | 70 | 77 | 425 | 37 |

Chemical Properties Of Ceramic

| Sio2 + Al2o3 | >92% | CaO | <1.0% |

| Si02 | >76% | MgO | <0.5% |

| Al2O3 | >17% | K20 + Na2O | <3.5% |

| Fe2o3 | <1.0% | Other | <1% |

Physical Properties Of Ceramic

| Water Absorption | <0.5% | Moh’s Hardness | >6.5 scale |

| Porosity | <1.0% | Acid Resistance | >85% |

| Maximum Operating Temperature | 1200°C | ||

Ceramic Raschig Ring

Application And Benifits

- It is widely used in high or low temperature conditions.

- Ceramic Raschig rings are widely used in the drying tower, absorption tower, cooling tower and washing tower in chemical, metallurgy, coal gas and industrial oxygen production industries.

- It is acid and alkali resistant.

- Due to its low price, it is widely accepted.