Manufacturer And Supplier

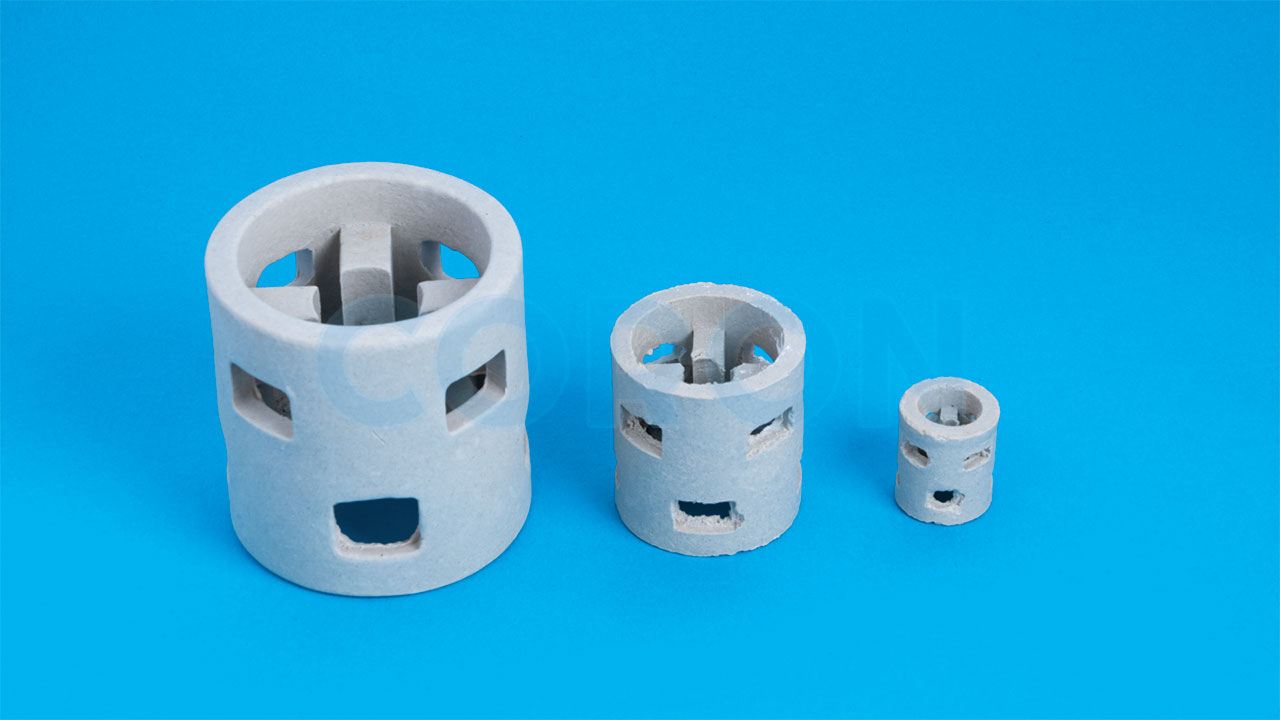

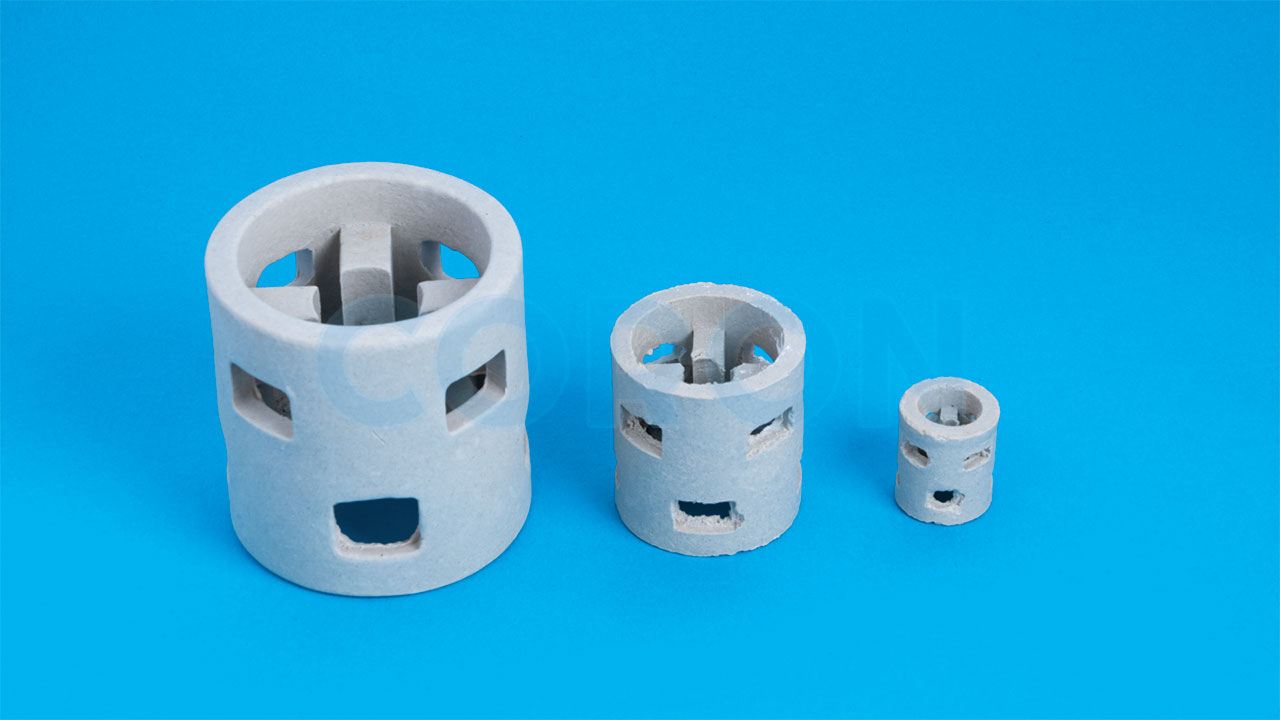

Ceramic Pall Ring

Pall Rings are a standard type of tower packing. The open structure ensures a regular flow through the packing and lowers the pressure drop.

There are two layers of windows on the cylinder wall and each layer has lingual bending inwards.

This design makes the surface area and voidage better, pall rings have a lower pressure drop.

Specifications

| Size | Surface Area m2/m3 |

Voidage % |

Bulk Density Kg/m3 |

Bulk Quantity Pcs./m3 |

|---|---|---|---|---|

| 25 mm | 210 | 73 | 700 | 53,500 |

| 38 mm | 180 | 75 | 650 | 15,000 |

| 50 mm | 130 | 78 | 600 | 6800 |

| 80 mm | 110 | 81 | 550 | 1950 |

Chemical Properties Of Ceramic

| Sio2 + Al2o3 | >92% | CaO | <1.0% |

| Si02 | >76% | MgO | <0.5% |

| Al2O3 | >17% | K20 + Na2O | <3.5% |

| Fe2o3 | <1.0% | Other | <1% |

Physical Properties Of Ceramic

| Water Absorption | <0.5% | Moh’s Hardness | >6.5 scale |

| Porosity | <1.0% | Acid Resistance | >85% |

| Maximum Operating Temperature | 1200°C | ||

Ceramic Pall Ring

Application And Benifits

- Ceramic Pall rings can be used in high and low temperatures conditions.

- It can be used in drying columns, absorbing columns, cooling towers, scrubbing towers in chemical industry, metallurgy industry, coal gas industry, oxygen producing industries, etc.

- It has excellent heat and acid resistance.