Manufacturer And Supplier

Raschig Ring Tower Packing

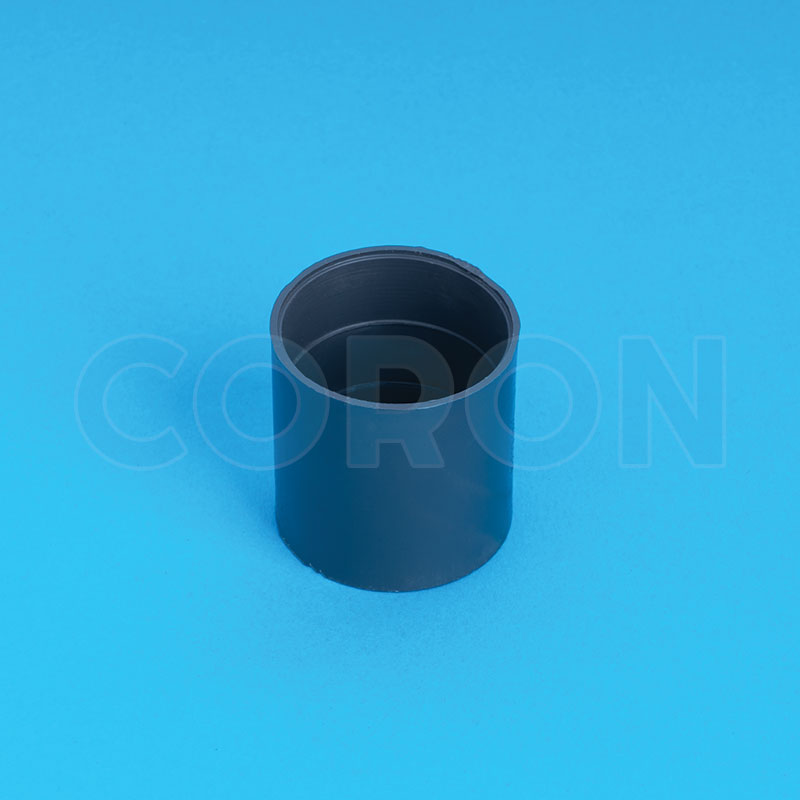

Raschig Ring Tower Packing is the first-generation tower packing.

Raschig Ring Tower Packing is basically a hollow cylinder.

Raschig Ring Tower Packing provides a large surface area within the volume of the column for interaction between liquid and gas or vapor.

Due to its low cost, Raschig Ring still remains one of the most widely used tower packings.

Specifications

| Size | Surface Area m2/m3 |

Pcs. Per m3 |

Voidage % |

|---|---|---|---|

| 25 mm | 205 | 51,000 | 86 |

| 38 mm | 130 | 13,500 | 90 |

| 50 mm | 93 | 6,500 | 92 |

| 76 mm | 90 | 2,050 | 94 |

| 100 mm | 55 | 1,850 | 96 |

Raschig Ring Tower Packing

Application And Benifits

- It is fit for various stripping, degassing, absorption and distillation processes, extensively used in petroleum industry, chemical industry, alkali industry and gas industry.

- Raschig Ring has low pressure drop and low energy consumption.

- It is widely applied in drying towers, absorption towers, cooling towers, washing towers and regeneration towers.

- They have very large void spaces.

- They are easy to Load & Unload.

Material Of Construction

- PP : Polypropylene

- PP-LTHA : Polypropylene - Long Term Heat Aging

- GFPP : Glass Reinforced Polypropylene

- PVDF : Polyvinylidene Fluoride

- PVC : Polyvinyl Chloride

- HDPE : High Density Poly Ethylene

- CPVC : Chlorinated Polyvinyl Chloride

- PFA : Perfluoroalkoxy

- FEP : Fluorinated Ethylene Propylene

- ETFE : Ethylene Tetrafluoroethylene

- ECTFE : Ethylene Chlorotrifluoroethylele

- PPS : Polyphenylene Sulfide

Note: Other Materials are available on request.