Manufacturer And Supplier

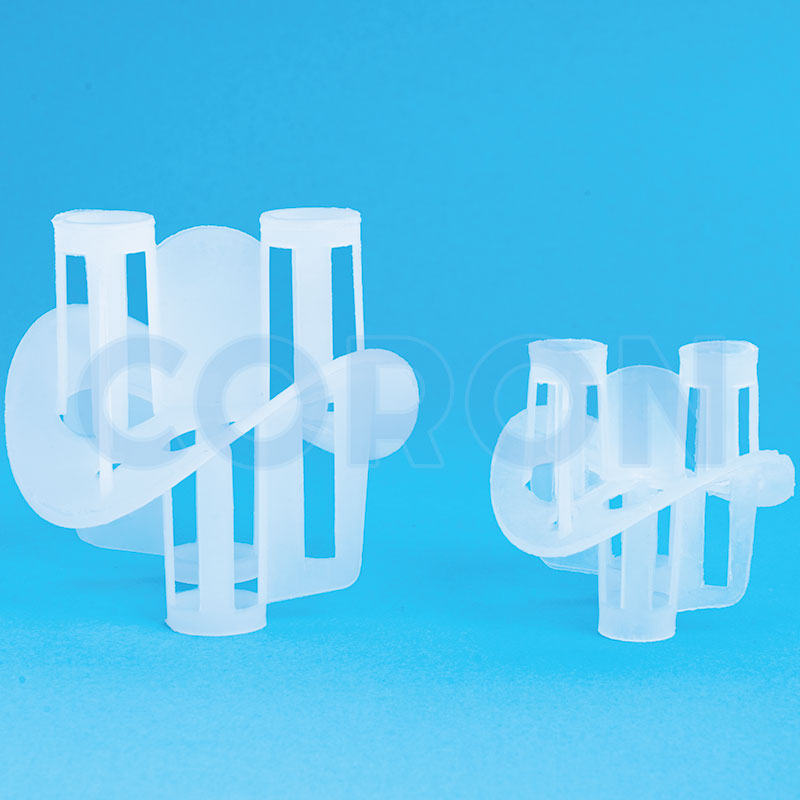

Helix Packing Ring

Helix Packing Ring is a very unique shaped random packing suitable for heavy liquids and gas flows.

This high-performance random packing offers an extra-large surface area that delivers lower pressure drops, low weights and high contacting efficiency.

Helix Packing Ring has a high void ratio, low pressure drops, low mass-transfer unit height, high flooding point, uniform gas-liquid contact, and high efficiency of mass transfer.

Specifications

| Size | Surface Area m2/m3 |

Pcs. Per m3 |

Voidage % |

|---|---|---|---|

| 50 mm | 107 | 8000 | 94 |

| 76 mm | 75 | 3420 | 95 |

| 100 mm | 55 | 1850 | 96 |

Helix Packing Ring

Application And Benifits

- Helix Packing Ring is mainly used in volatile gas stripping, water degasifying and scrubbing atmospheric pollutants from waste gas.

- They are also used in Gas Absorption, Acidic gas desorption system, Washing, Fertilizer Production.

- Due to its unique shape, it provides high flooding and minimizes pressure drop while retaining a large surface area to maximize gas-liquid contact.

- Helix is designed in a way that is very easy to install without risking damage to the tower.

- It is also very convenient for cleaning, reducing downtime when maintenance is required.

Material Of Construction

- PP : Polypropylene

- PP-LTHA : Polypropylene - Long Term Heat Aging

- GFPP : Glass Reinforced Polypropylene

- PVDF : Polyvinylidene Fluoride

- PVC : Polyvinyl Chloride

- HDPE : High Density Poly Ethylene

- CPVC : Chlorinated Polyvinyl Chloride

- PFA : Perfluoroalkoxy

- FEP : Fluorinated Ethylene Propylene

- ETFE : Ethylene Tetrafluoroethylene

- ECTFE : Ethylene Chlorotrifluoroethylele

- PPS : Polyphenylene Sulfide

Note: Other Materials are available on request.