Manufacturer And Supplier

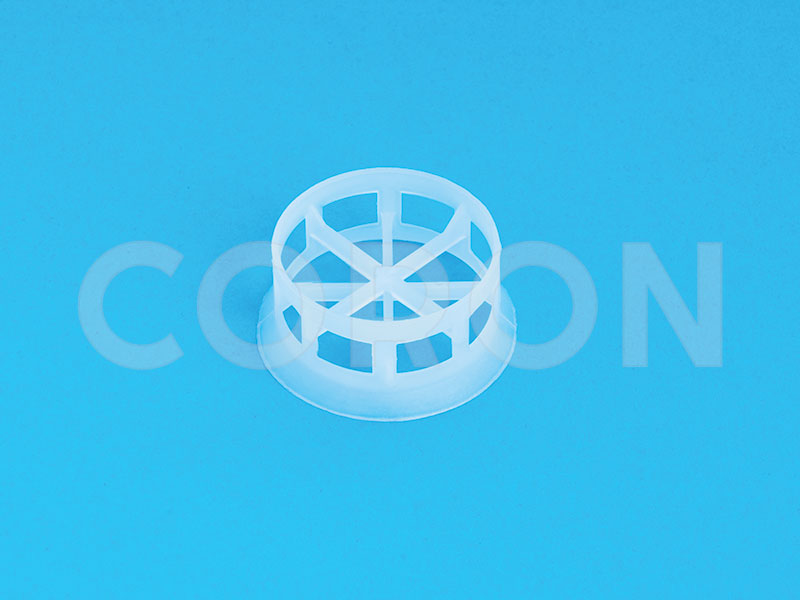

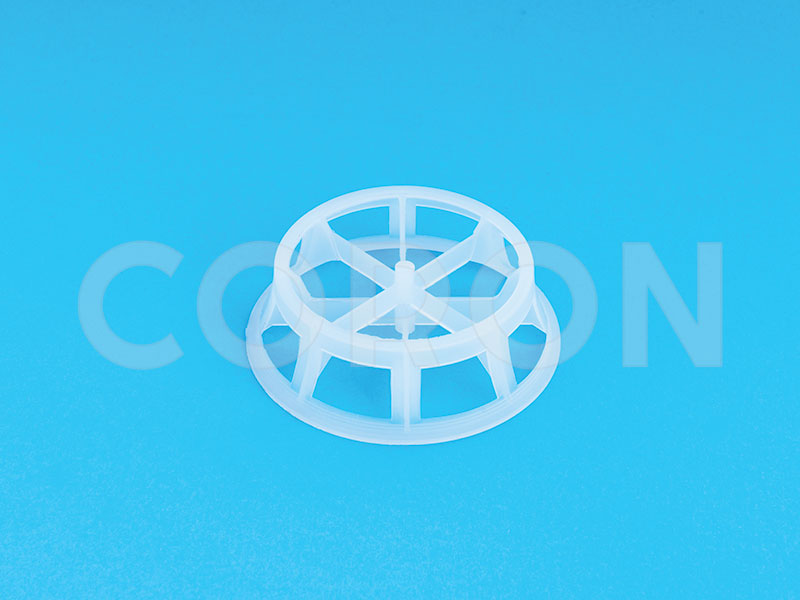

Plastic Cascade Mini Ring

Plastic Cascade Mini Ring (CMR) is a type of high-performance plastic random packing.

Its vertical axis orientation allows more fluids to pass through the cylinder.

As solids are easily washed away by fluids, CMR has good fouling resistance.

It is a product specifically designed for reducing pressure drop and increase plant capacity.

Specifications

| Type | Surface Area m2/m3 |

Voidage % |

Pcs. Per m3 |

Packing Factor F |

|---|---|---|---|---|

| #1" | 250 | 92 | 70,000 | 32 |

| #1A | 140 | 95 | 26,500 | 30 |

| #2A | 115 | 96 | 7,000 | 18 |

| #3A | 90 | 96.5 | 4,500 | 12 |

Plastic Cascade Mini Ring

Application And Benifits

- Cascade Mini Ring (CMR) is widely used in absorption, extraction, scrubbing, stripping and heat transfer applications.

- Cascade Mini Ring (CMR) is generally used in desulfurization & decarbonization.

- Cascade Mini Ring (CMR) supports high transfer rates, excellent gas and liquid dispersion characteristics and good fouling resistance.

- High capacity and low pressure drop with high mechanical strength that allows use in deep beds.

- Smaller design offers excellent structural integrity, reducing the risk of deformation in high-capacity towers.

- Low packing factor permits increased hydraulic capacity.

Material Of Construction

- PP : Polypropylene

- PP-LTHA : Polypropylene - Long Term Heat Aging

- GFPP : Glass Reinforced Polypropylene

- PVDF : Polyvinylidene Fluoride

- PVC : Polyvinyl Chloride

- HDPE : High Density Poly Ethylene

- CPVC : Chlorinated Polyvinyl Chloride

- PFA : Perfluoroalkoxy

- FEP : Fluorinated Ethylene Propylene

- ETFE : Ethylene Tetrafluoroethylene

- ECTFE : Ethylene Chlorotrifluoroethylele

- PPS : Polyphenylene Sulfide

Note: Other Materials are available on request.